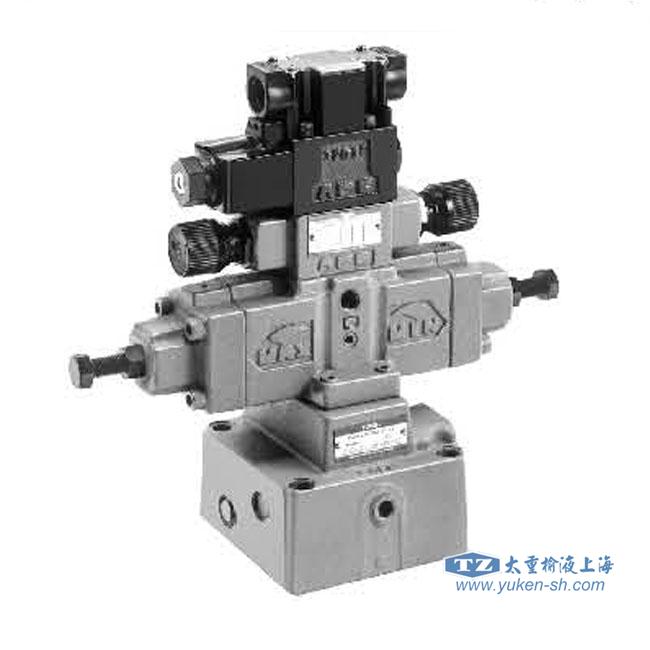

Flow control of these valves is continuously made by a hydraulically operated pilot piston mechanism which controls opening area ofthe orifice of the valve. With the use of these valves, shockless operation either in acceleratio or deceleration can be obtained.

Pilot Operated Flow Control Valves/ Pilot Operated Flow Control and Check Valves Model Number Designation

1. Both solenoid operated directional (DSG-01) and modular valve (MSW-01) can be used as a pilot valve. If no pilot valve is required, there is no needs to specify the coil type and the electrical connection type of solenoid operated directional valve.

2. The coil types are same as those for DSG-01 Series solenoid operated directional valves.

3. Pres. compensator stroke adjustment: Can reduce jumping at the start of the actuator.

Instructions

1) While the solenoid operated directional valve off (④ shown left) The flow rate is set by the minimum flow adjustment screw and the actuator operates at the minimum speed setting.

2)When the solenoid operated directional valve is turned on (① shown left) The flow rate is shifted from minimum(④shown left) to maximum (②shown left) and the actuator speed is also shifted likewise. The switching time(T1) can be set by the pilot flow adjustment dial ①.

3)When the solenoid operated directional valve is turned off , The flow rate is shifted from maximum to minimum and the actuator speed is also shifted likewise. The switching time(T2) can be set by the pilot flow adjustment dial③.

2. Tightening of flow adjustment screws and dials

To adjust flow rates, slacken the lock nut or the dial setting screw. After adjustments, tighten the lock nut or the dial.

3. Min. required pressure difference

The minimum differential pressure between inlet and outlet port is required to obtain the optimum pressure compensation. It varies according to the flow rate to be set. For details, please refer to the performance curves.

4. Line filter

To carry out flow adjustments by as small degree as 2L/min or less 10 μm or finer and install it near the valve inlet.

Move the mouse to view larger image

Move the mouse to view larger image